Understand how lab grown diamonds are made and the two types of manufacturing processes - High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD), that are used to make lab grown diamonds.

In this article, we’ll provide comprehensive insights into how scientists use these two manufacturing processes to create lab grown diamonds, as well as provide some context on the market share and values of lab grown diamonds vs. natural diamonds and how consumer sentiment is slowly shifting.

Lab grown diamonds, otherwise known as lab, made or man-made diamonds are diamonds that are created in controlled, laboratory conditions.

Unlike cubic zirconia and moissanite, lab made diamonds are real diamonds that share the same physical, chemical, and optical properties as naturally mined diamonds. While natural diamonds form over billions of years under high pressure and extreme temperatures within the earth’s mantle, lab made diamonds are produced using an advanced technological process that yields the same outcome.

As you might imagine, the process for creating diamonds in a laboratory environment occurs in a much shorter timeframe and allows greater control over the end outcome.

Choosing between lab grown and natural diamonds is a relatively new decision for consumers shopping for engagement rings and other jewellery pieces. The new option affords consumers greater flexibility in finding a diamond that suits their budget and their desired aesthetic.

Both lab grown and natural diamonds are composed of carbon and share the same properties of hardness, refractive index, and the potential for different clarity and colour variations.

As we know, lab grown diamonds form deep within the earth’s crust over a period of more than 1-billion years. Additionally, naturally occurring diamonds require significant resources to extract and, when the process is not properly controlled, can cause environmental disruption.

Conversely, lab grown diamonds have a lower environmental footprint and require less land, water, and environmental disruption to produce. Additionally, lab grown diamonds are generally much less expensive to produce with the equivalent lab grown diamond costing around 20-40% cheaper than their natural diamond equivalent. Just like natural diamonds, the cost of man-made diamonds will fluctuate based on the quality (refer to the 4Cs) of the diamond.

The history of lab grown diamonds traces back to General Electric (GE) who are credited with creating the first lab-grown diamonds in the 1950s. Prior to this, there is some (limited) historical evidence that lab grown diamonds may date back as far as the late 1800s, however, this information is patchy and cannot be properly verified.

The breakthrough work by General Electric (GE) conducted in the 1950s employed the high-pressure, high temperature (HPHT) to transform graphite, a form of carbon, into diamonds. This breakthrough laid the groundwork for the production of larger, gem-quality synthetic diamonds which eventually led to the Chemical Vapor Deposition (CVD) method of creating man made diamonds.

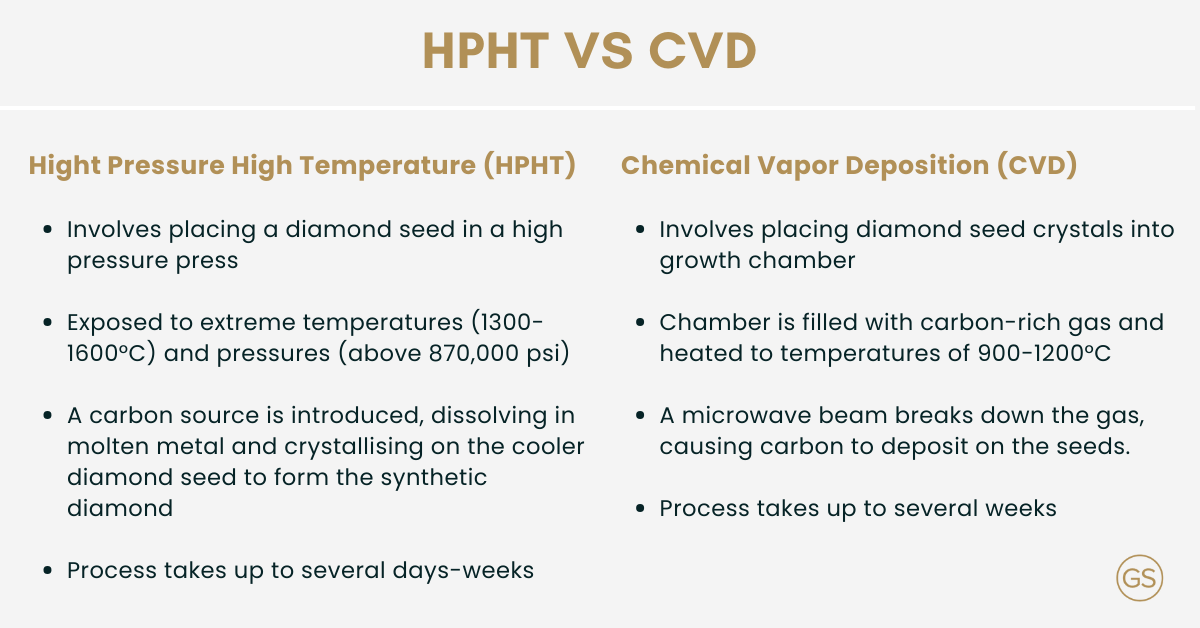

The manufacturing process for lab grown diamonds can be neatly segmented into two methods: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

High Pressure High Temperature (HPHT) lab grown diamonds are created using a process that closely mimics the natural conditions under which diamonds are produced in the Earth’s mantle. The process for creating HPHT lab made diamonds looks like this:

Preparation of seed crystal: a small diamond seed is placed in the machinery which is used as a seed for diamond growth.

Heating & pressurising: The growth chamber containing the seed crystal is heated to extreme temperatures between 1 ,300 to 1,600 °C, with pressures exceeding 870,000 pounds per square inch.

Dissolution and Crystal Growth: Inside the heat and pressure chamber, a carbon source (typically graphite) dissolves in a molten flux of metals like iron, nickel, or cobalt. This lowers the temperature and pressure needed for diamond growth. The high-purity carbon source then precipitates onto the diamond seed, gradually forming a synthetic diamond.

Diamond Development: Once the process above has been completed, there will be a period of several days to a few weeks where the crystallisation process takes place. During this time, the carbon material migrates through the flux and towards the cooler diamond seed where it crystallises it.

Cutting and Polishing: Once the diamond has been grown, it is then cut and polished by skilled lab grown diamond technicians who are responsible for transforming the diamond into a faceted gemstone.

Chemical Vapor Deposition (CVD) lab made diamonds are produced by depositing carbon atoms onto a substrate in a lab using a mixture of different gases. The process involves a more technologically advanced approach to lab grown diamond production and looks like this:

Seed Crystal Preparation: Diamond seed crystals are placed in a growth chamber designed for the CVD process.

Gas Introduction and Heating: The chamber is filled with a carbon-containing gas (usually a mix of hydrogen and methane) and heated to temperatures around 900-1200°C.

Carbon Precipitation: A microwave beam breaks down the gas molecules, causing carbon to precipitate from a plasma cloud and deposit onto the seed crystal.

Diamond Growth Cycles: Diamonds are periodically removed every few days for polishing to remove non-diamond carbon. They are then put back in the chamber to continue growing. This cycle can be repeated several times, and the entire growth process typically spans three to four weeks.

Diamond Harvesting and Post-Processing: After the growth process, the synthetic diamond crystals are harvested. They often have a rough edge of black graphite and a brown colour, which can be removed by subsequent HPHT annealing.

Cutting and Polishing: Just like HPHT diamonds, once the process is complete, CVD diamonds are then ready to be cut and polished into their final form by skilled technicians, transforming them into sparkling gemstones.

The key difference between HPHT and CVD diamonds is that they have different growth patterns. When inspected by a professional jeweller, they should be able to tell the difference between a HPHT and CVD produced lab grown diamond by inspecting the different crystal structures.

Today, lab grown diamonds occupy a significantly smaller market when compared to natural diamonds, however, the consumer sentiment towards lab-made diamonds is quickly changing and spurring significant growth. As of 2023, lab grown diamonds account for roughly 7-10% of all new diamond sales in Australia.

As for where consumers are buying lab grown diamonds, around 65% of all lab grown diamond sales come from the bridal sector in the form of lab grown diamond engagement rings and lab grown diamond wedding rings. As consumer sentiment shifts towards new, sustainable diamond practices, it is predicted that the market share for lab grown vs. natural diamonds will continue to climb.

When it comes to buying lab grown diamonds vs. natural diamonds, one of the biggest points of contention for consumers comes when we look at resale values. Despite consumer demand increasing in the retail sector, the current market shows that resale values of lab grown diamonds still have a long way to go. Increasing supply underscored by ever-improving improved technology and production improvements mean that the market for lab grown diamonds continues to demonstrate volatility.

As a rule of thumb, buyers can expect to pay around 20-40% less for a lab grown on the new retail market. Conversely, on the resale market, the value of lab grown diamonds is less than half of their equivalent natural counterparts.